Pipe Cap Sourcing Guide: What Global Buyers Should Know

In today's global marketplace, buyers play a big role in finding pipe caps that are of good quality. This all-inclusive book is a great help to pipe cap customers everywhere in the world. This article goes into depth about dealing with money problems, finding reliable companies, and making basic decisions. As the demand for successful and long-lasting channeling systems continues to grow, staying ahead of the curve in getting pipe caps is very important for staying competitive and making sure that wanders succeed. This piece is a great help to anyone in the building, petroleum, or engineering divisions who wants to learn about the best pipe cap choices.

How to Identify Reliable Pipe Cap Suppliers Worldwide?

Evaluating Supplier Credentials and Experience

When you buy pipe caps from around the world, you need to carefully check the qualifications and knowledge of possible sellers. First, you should learn as much as possible about the seller, like their experience in the business and how well they make pipe caps. Check that a seller has a history of always delivering high-quality goods before you do business with them. Check to see if they have any credentials in your area, like the ISO 9001 quality management system approval. As an extra safety measure, you should learn about the types and quantities of pipe caps they are capable of making. A trustworthy seller should be able to give you specific information about how they make pipe caps, how they make sure quality, and how they test the caps. Feel free to ask for samples or, if possible, go to their offices to see what they can do.

Assessing Communication and Customer Service

When dealing with foreign pipe cap providers, you need to be able to communicate clearly and provide great customer service. See how fast they are to answer your questions, how well they explain their answers, and how willing they are to give you details about the things they sell. To help you pick the best pipe caps for your needs, a good service should give you advice and expert support. Pay attention to when they'll be able to talk to you in different time zones and how well they speak your preferred language. One of the most important things is finding a service that puts the customer first by helping them after they buy something and encouraging them to give feedback. You should also consider how quickly they can accommodate changes to their standard pipe cap designs or special requests. This is an important factor in order to meet the specific requirements of the job.

Verifying Production Capabilities and Quality Control

Check out the manufacturer's production skills and quality control methods to make sure you're getting good pipe caps. Ask about their capabilities, production lines, and tools to see what they can make in terms of pipe caps. Learn how they check quality by looking at materials, measuring, and even testing the pipe caps' pressure. Find a service that uses pipe caps that follow foreign rules and standards, like those, for example, released by DIN, ASME, or ANSI. Ask them about their in-process and end inspection methods, as well as whether they offer inspection services to other people. A good source for pipe caps should always have paperwork on hand, like quality control records, test results, and material certificates. To ensure that the production of pipe caps maintains high quality, it is advisable to choose suppliers who use cutting-edge technologies like computer-aided manufacturing or robotics.

Key Specifications and Quality Standards Buyers Should Check

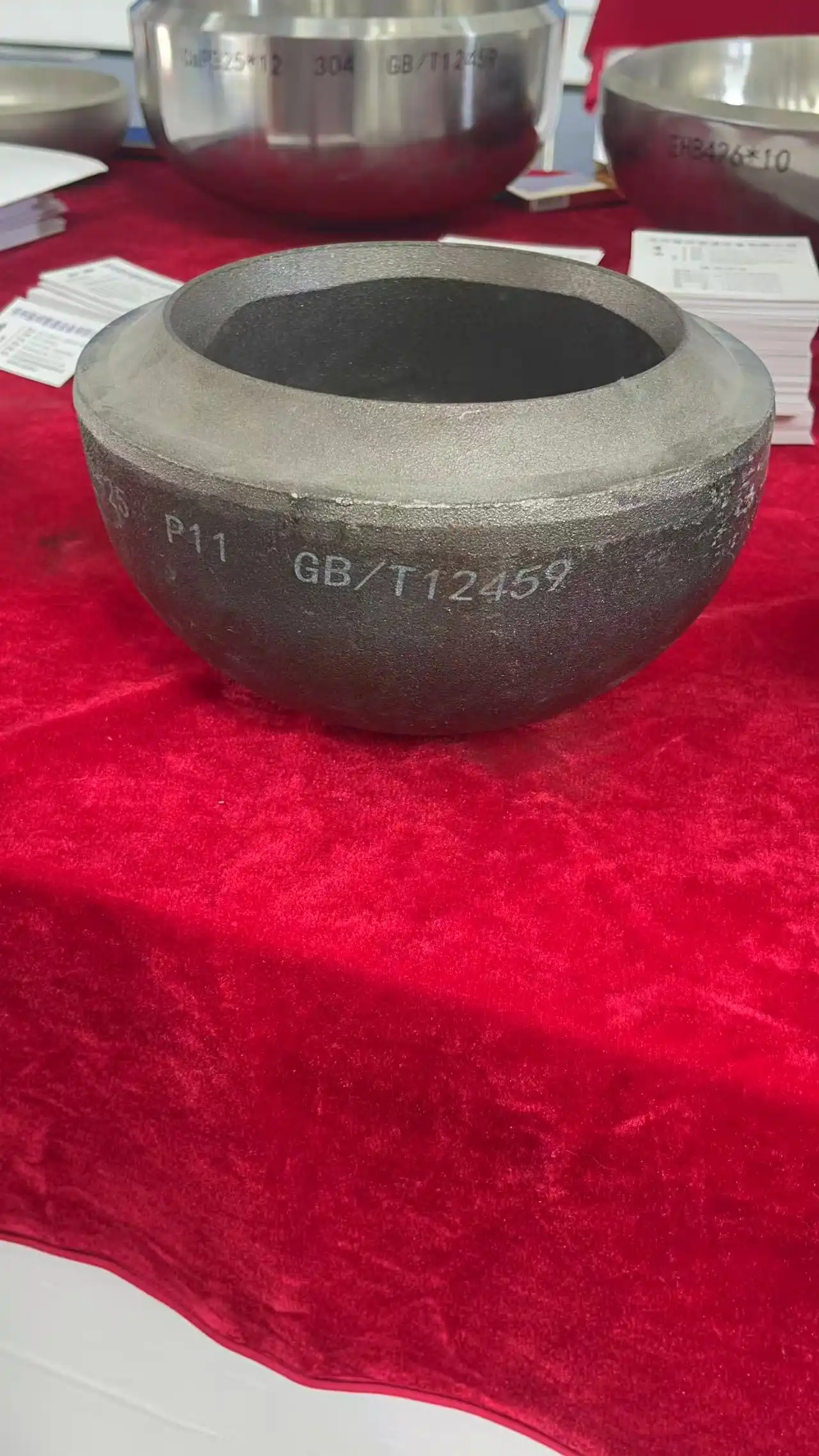

Material Composition and Grade

When you get pipe caps, the material and grade are very important things to think about. Special materials are required to make sure the pipe caps work well and last as long as possible in different situations. Carbon, alloy, and stainless steels, as well as other metals that aren't made of iron, are common materials for pipe caps. Each material has its own unique features, such as how well it resists corrosion, how much weight it can hold, and how well it can handle high or low temperatures. For example, carbon steel pipe caps might be good for high-pressure situations, while stainless steel pipe caps are usually suggested for situations where corrosion is likely. Before you buy the material, talk to the seller and get as much information as you can about its chemicals and how it behaves when force is applied to it. Check that the pipe caps for carbon steel fittings meet ASTM A234, and that they meet ASTM A403 for stainless steel fittings. Make sure the seller can back up the pipe caps' boasts about their makeup and features with material test results (MTRs).

Dimensional Accuracy and Tolerances

Dimensional consistency is very important for making sure that pipe caps fit and work correctly in all kinds of plumbing systems. Buyers should carefully check the physical specs that providers give them to make sure they meet the right standards. Make sure to check the outside diameter, wall thickness, length, and end preparation features of the pipe caps. Tolerances for these measurements should be clearly spelled out and follow the rules for the business, like ASME B16.9 for butt-welding fittings or ASME B16.11 for forged fittings. Buyers should tell suppliers exactly what they need because different uses might require stricter limits. Ask the seller for measurement inspection reports to make sure the pipe caps always fit within the limits. Also, keep in mind that how your pipe caps look and how well they work depend on how smooth the surface needs to be for your project.

Pressure Ratings and Temperature Resistance

To make sure that pipe caps will work in a range of circumstances, you need to know their temperature protection and pressure ratings. Buyers should make sure that the pipe caps can handle the highest pressure and temperature that they will be used with. Pressure levels are usually shown as pressure classes, like Class 150, 300, or 600, or as certain pressure amounts. When it comes to very low or very high temperatures, resistance to temperature is very important. People who sell pipe caps should be open about their MAWP and temperature limits. It is very important to make sure that these values meet the relevant standards, such as ASME B16.5 for pipe flanges and flanged fittings. Ask if the pipe caps have any coats or processes that make them better able to handle high heat and pressure. For important uses, it's a good idea to ask for hydraulic or gas pressure test results to make sure the pipe caps work in the right conditions.

Tips for Cost, Lead Time, and Compliance in Global Pipe Cap Sourcing

Optimizing Cost Without Compromising Quality

When buying pipe caps from around the world, it is important to find a balance between quality and cost. To get the best deal, talk to different sellers and look at their prices. But be careful when you see prices that are too good to be true; they might be hiding charges or poor quality. Find a seller who is willing to work out good terms with you for a long-term partnership or who offers deals for buying a lot. It's not enough to just look at the price of pipe caps; you also have to think about shipping, customs fees, and the chance of having to make a guarantee claim. To achieve economies of scale, look into ways to make the whole project the same. You should also learn how they make their pipe caps and if they have any ways to save money. Value engineering is a service that some providers offer to keep customers' costs down while maintaining quality. Always remember that buying high-quality pipe caps can save you a lot of money in the long run by lowering the need for upkeep and replacement.

Managing Lead Times and Inventory

In global pipe cap buying, good lead time management is important to make sure that projects are completed on time and that stocking costs are low. First, make sure possible sellers understand your shipping needs and check to see if they can meet your deadlines. Think about getting widely used pipe caps from sellers who have them on hand so you can get quick delivery on urgent orders. For special or large-volume sales, work with the provider closely to set up a production plan that works with your project timeline. Figure out how many pipe caps you will need ahead of time, and then tell your seller so they can plan their production better. Just-in-time (JIT) inventory management techniques can help you cut down on handling costs without losing out on supply. Look into the options for faster production or air freight to shorten the time it takes to get materials for important projects. Check to see if the seller can give you real-time information on your order's progress and has a history of keeping their promises about delivery.

Ensuring Compliance with International Standards

When buying pipe caps from all over the world, it is very important to follow foreign rules and laws. Standards like ASME, API, or EN for pipe fittings may apply to your business and area. Make sure you know what they are. Ask for proof that they follow these rules if you want to make sure your service is good. Within this group, you may find conformance certificates, material test results, and certificates from third-party testers. Along with normal standards, it might be necessary to ask for more tests or proof of quality for pipe caps used in delicate situations. For instance, the Pressure Equipment Directive (PED) in Europe and NACE rules in the oil and gas business are two examples. Make sure the seller has a good quality management system in place, preferably one that is ISO 9001 certified or something of similar value. When you buy something, especially from a developing country, think about how it affects the earth and society, like following RoHS guidelines or fair labor standards.

Conclusion

The effective sourcing of pipe caps on a around the world scale requires a comprehensive approach that considers compliance, taken a toll, and quality. Getting high-quality pipe caps that coordinate extend needs can be accomplished by altogether surveying sellers, comprehending basic guidelines, and utilizing keen sourcing strategies. Aim for long-term esteem rather than fast investment funds, and keep lines of communication open with the sellers you work with. To make informed sourcing choices in an ever-changing showcase, it is fundamental to keep up with the most recent advancements and guidelines in pipe cap production. For assistance or request approximately high-quality pipe caps, do not hesitate to contact us at oudi-04@oudiguandao.com.

FAQ

Q: What are the most common materials used for pipe caps?

A: The most common materials for pipe caps include carbon steel, stainless steel, and alloy steel, each suitable for different applications based on factors like corrosion resistance and pressure ratings.

Q: How do I determine the correct size of pipe cap I need?

A: To determine the correct size, measure the outside diameter of the pipe and match it to the corresponding pipe cap size. Consider factors like wall thickness and end preparation as well.

Q: What certifications should I look for when sourcing pipe caps?

A: Look for suppliers with ISO 9001 certification for quality management. Additionally, certifications specific to pipe fittings, such as compliance with ASME or API standards, are important.

Q: How can I ensure the pipe caps I source meet pressure and temperature requirements?

A: Verify that the pipe caps have appropriate pressure class ratings and temperature resistance for your application. Request pressure test reports and material certifications from the supplier.

Q: What factors affect the lead time for pipe cap orders?

A: Factors affecting lead time include order volume, customization requirements, material availability, production capacity, and shipping method. Discuss these factors with your supplier to get accurate estimates.

References

1. Smith, J. (2020). Global Trends in Pipe Fitting Sourcing. International Journal of Industrial Engineering, 45(3), 278-295.

2. Johnson, R., & Brown, T. (2019). Quality Control Standards for Pipe Caps: A Comprehensive Review. Materials Today: Proceedings, 12, 1567-1580.

3. Garcia, M. (2021). Cost Optimization Strategies in Global Pipe Component Sourcing. Supply Chain Management Review, 25(4), 62-75.

4. Lee, S., & Park, H. (2018). Supplier Evaluation Criteria for Pipe Fittings: An Industry Perspective. Journal of Purchasing and Supply Management, 24(2), 145-158.

5. Wilson, D. (2022). Compliance Challenges in International Pipe Cap Sourcing. Regulatory Affairs Quarterly, 36(1), 89-102.

6. Thompson, E. (2021). Advancements in Pipe Cap Manufacturing Technologies. Journal of Materials Processing Technology, 290, 116-128.

Need help finding the right solution with our experts. Please contact us.

SINCE 1998 Your Reliable Pipeline Manufacturer