ASTM A105 vs A234 Carbon Steel Fittings: Which Should You Choose

People often look at ASTM A105 and ASTM A234 when they are picking out carbon steel parts for industrial pipe systems. Both of these standards are met by many Carbon Steel Pipe Fittings, but they are used for different things. Engineers, project managers, and people who buy things need to know the differences between ASTM A105 and A234 carbon steel parts in order to make smart decisions. This blog post will talk about the key features, benefits, and right ways to use both ASTM A105 and A234 carbon steel fittings. These two standards are different, and we can help you pick the one that works best for your job. Please read this whole guide carefully. It will help you choose the best carbon steel fittings for your pipe system, no matter if you work in the oil and gas, chemical, or power industries.

What are the main differences between ASTM A105 and A234 carbon steel fittings?

Chemical composition and manufacturing process

ASTM A105 and A234 standards call for pipe parts made from carbon steel to be made in different ways and with different chemicals. A lot of ASTM A105 fittings are made by forging carbon steel, which makes the microstructure thick and even. The forging process makes the parts stronger and lasts longer, so they can be used in settings with a lot of pressure. On the other hand, ASTM A234 fittings are usually made by shaping and heating lines that are either seamless or welded. Depending on the grade, like WPB or WPC, the materials that go into making A234 fittings may be different. They can be used in more places and in more ways because of this.

Mechanical properties and performance

To know how well carbon steel pipe fittings work and what they're best for, you need to know a lot about their mechanical properties. Most of the time, ASTM A105 fittings have better tensile and yield strengths than A234 fittings. Because of these things, A105 valves work great in places with a lot of heat and pressure. Also, A105 valves are more likely to be flexible and less likely to break when they are hit. This can be useful when pressure or temperature changes quickly. ASTM A234 fittings still have good mechanical qualities, but they are mostly used because they are cheap, flexible, and work well in warm and dry conditions.

Available shapes and sizes

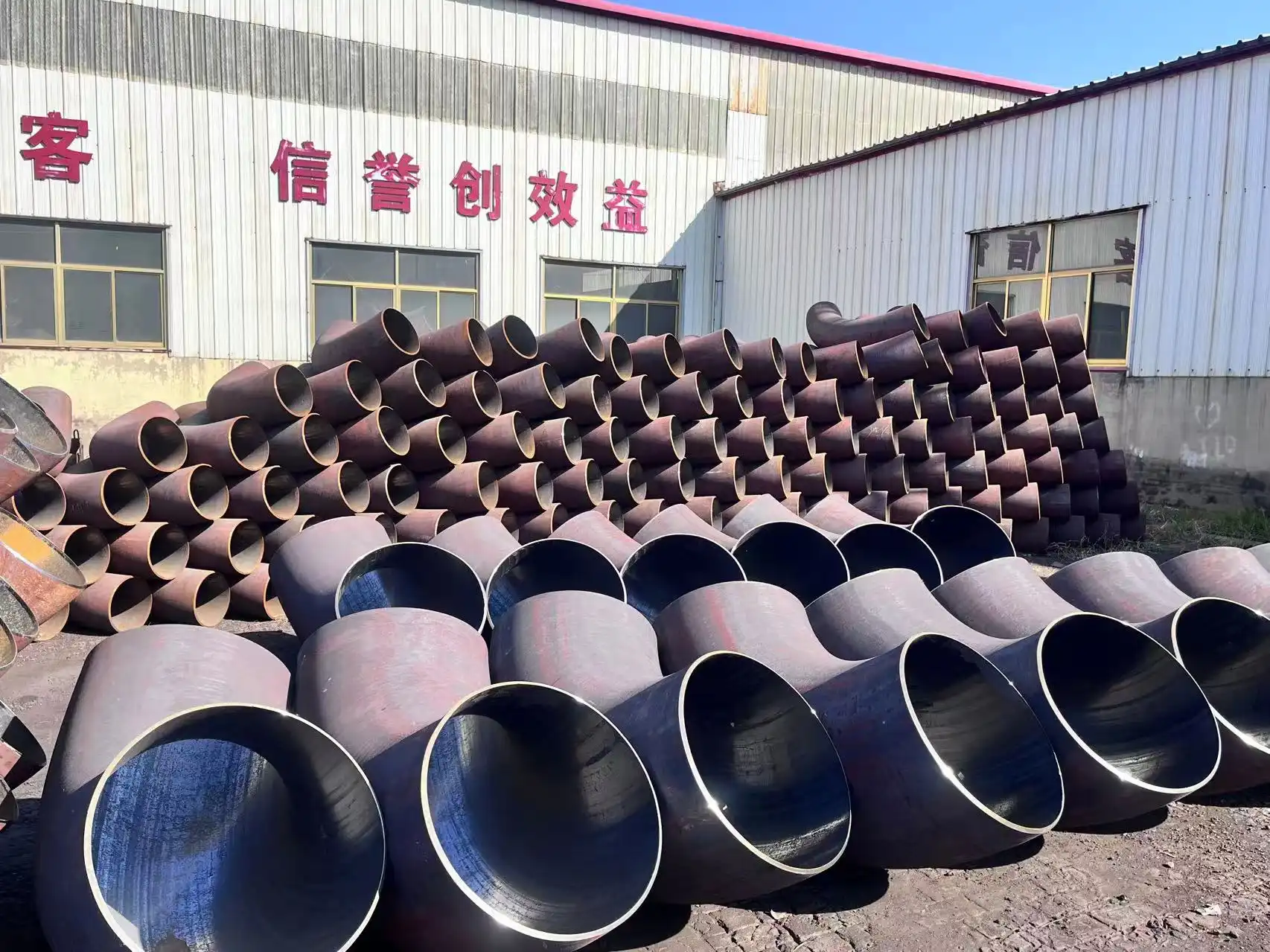

Steel pipe valves that are ASTM A105 and A234 come in a lot of different types and sizes. ASTM A105 has a lot of different cast forms for fittings, like flanges, unions, and socket-weld fittings. They are often used on pipes that are up to 4 inches across. But ASTM A234 fittings, such as caps, elbows, tees, and reducers, come in more styles and sizes. There are a lot of different kinds of A234 fittings, from very narrow ones to ones that fit big pipes. To put it another way, they can be used in more situations and places.

How do ASTM A105 and A234 carbon steel fittings compare in terms of cost and availability?

Initial procurement costs

It's important to look at both the short-term and long-term costs when you want to know how much carbon steel pipe fittings cost. Most of the time, ASTM A105 fittings cost more up front than A234 fittings because they are cast and made of better materials. A105 fittings, on the other hand, may last longer and cost less to maintain over time because they are stronger and last longer. Because ASTM A234 valves are easier to find and can be made in a number of different ways, they usually cost less at first. Because of this, they are a good choice for projects that need to stay within a budget or situations where the high-performance of A105 is not needed.

Supply chain considerations

The cost and time of a job can be greatly affected by the availability of carbon steel pipe fittings. Even though ASTM A105 fittings are very popular, they may have longer lead times because they are forged in a special way and are in higher demand in some businesses. When time is of the essence, this can be a very important thing to think about for urgent jobs or replacements. But ASTM A234 valves are usually easier to find because they come from more than one source. This can mean shorter lead times and better prices. It's important to look at the unique needs of your project and weigh them against the fitting standards and lead times when thinking about the supply chain.

Long-term cost-effectiveness

You should look at more than just the price of the clothes to see how much they will save you over time. ASTM A105 valves may last longer and need less upkeep because they work better and rust less often. In some cases, this could mean that the pipe system will cost less over its whole life. Also, A105 fittings can handle higher pressures and temperatures, so when things get tough, you might not have to update or replace them as often. If things get rough, ASTM A234 parts may need to be fixed or changed more often. But when things aren't too bad, they can still be very useful. How something is used, how well it works, and how well it is kept will determine how cost-effective it is in the long run.

What are the key factors to consider when choosing between ASTM A105 and A234 carbon steel fittings for specific applications?

Operating pressure and temperature

When you choose carbon steel pipe parts, one of the most important things to think about is how hot and how much pressure will be used. It is best to use ASTM A105 valves because they last longer when there is a lot of pressure and heat. As high as 6,000 psi and 800°F (427°C), they can be used in tough places like power plants or oil and gas fields. ASTM A234 fittings can still work in low temperatures and pressures, but they're mostly used when things aren't too bad. What is the highest working pressure and temperature of your system? This will help you choose the best-fitted standard.

Corrosion resistance and material compatibility

When you pick out Carbon Steel Pipe Fittings, there are many things to think about. This is very important if they are going to be used in rough conditions or with fluids that rust. Because they have a stronger microstructure and more metal, ASTM A105 fittings tend to last longer than A234 fittings when it comes to rust. Because of this, A105 valves work better in industries that process chemicals or in harsh marine settings with lots of materials that wear down metal. Since you use both A105 and A234 parts, they might need extra rust protection, like coats or cathodic protection. Don't forget this. It is important to think about the material of the fittings and whether the fluids being moved won't damage the material. Also, different metals rusting could be a problem.

Industry standards and regulatory requirements

Carbon steel pipe valves that meet government and industry standards are very important for what they need them to do. Either ASTM A105 or A234 fittings are used a lot in many fields, but some may have specific needs or tastes. On the other hand, ASTM A105 fittings are often chosen by the oil and gas industry for high-pressure uses since they are harder and more reliable. ASTM A234 valves, on the other hand, are commonly used in HVAC systems and other industrial pipe systems. For process lines, ASME B31.3 and API 6A are good standards to check. These will help you make sure you're following the rules. You should also think about any rules or project-specific needs that could affect your choice between A105 and A234 fits.

Conclusion

Finally, the choice between ASTM A105 and A234 carbon steel parts depends on several factors, including the intended use, cost, and specific requirements of the task. Even when there is a lot of pressure and heat, ASTM A105 valves are very strong and last a long time. For moderate operating situations, ASTM A234 fittings are flexible and cost-effective. By carefully thinking about the things this blog post talks about, you can make a choice that will make your pipe system work well and last a long time. Cangzhou Oudi Pipe Manufacture Co., Ltd. has been a top manufacturer since 1998. They can help you with your project and provide high-quality carbon steel pipe fittings. Contact us at oudi-04@oudiguandao.com for personalized assistance in selecting the right fittings for your project.

FAQ

Q: What is the main difference between ASTM A105 and A234 fittings?

A: ASTM A105 fittings are forged and suitable for high-pressure applications, while A234 fittings are manufactured from seamless or welded pipe and are more versatile in terms of shapes and sizes.

Q: Which fitting standard is better for high-temperature applications?

A: ASTM A105 fittings generally perform better in high-temperature applications due to their superior mechanical properties.

Q: Are ASTM A234 fittings more cost-effective than A105 fittings?

A: ASTM A234 fittings typically have a lower initial cost, but the long-term cost-effectiveness depends on the specific application and operating conditions.

Q: Can ASTM A105 and A234 fittings be used interchangeably?

A: While they may be interchangeable in some applications, it's crucial to consider the specific requirements of your project and consult relevant industry standards before substituting one for the other.

Q: Which fitting standard offers better corrosion resistance?

A: ASTM A105 fittings generally offer better corrosion resistance due to their denser microstructure and higher alloy content.

References

1. ASTM International. (2021). ASTM A105/A105M-21 Standard Specification for Carbon Steel Forgings for Piping Applications.

2. ASTM International. (2019). ASTM A234/A234M-19 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service.

3. American Society of Mechanical Engineers. (2018). ASME B16.11-2016 Forged Fittings, Socket-Welding and Threaded.

4. Peng, L. C., & Peng, T. L. (2009). Pipe Stress Engineering. ASME Press.

5. Smith, P. (2018). Piping Materials Guide: Selection and Applications. Elsevier.

6. Nayyar, M. L. (2000). Piping Handbook (7th ed.). McGraw-Hill Education.

Need help finding the right solution with our experts. Please contact us.

SINCE 1998 Your Reliable Pipeline Manufacturer